Ultimate Guide to CNC Operating Skills for FANUC

CNC (Computer Numerical Control) machines are essential tools in modern manufacturing. They are used to produce a wide variety of parts, from simple to complex, with high precision and accuracy. FANUC is one of the leading manufacturers of CNC machines, and their machines are known for their reliability, durability, and ease of use.

If you are new to CNC machining or if you want to improve your skills, this guide will provide you with everything you need to know about CNC operating skills for FANUC. We will cover the basics of CNC machining, including the different types of CNC machines, the different types of CNC controls, and the different types of CNC programming. We will also provide you with some tips and tricks for getting the most out of your FANUC CNC machine.

There are many different types of CNC machines, each designed for a specific purpose. The most common types of CNC machines include:

5 out of 5

| Language | : | English |

| File size | : | 613 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 21 pages |

| Lending | : | Enabled |

- Vertical Machining Centers (VMCs): VMCs are used to machine parts in three axes (X, Y, and Z). They are typically used for milling, drilling, and tapping operations.

- Horizontal Machining Centers (HMCs): HMCs are used to machine parts in four axes (X, Y, Z, and A). They are typically used for milling, drilling, and tapping operations on large or complex parts.

- Turning Centers: Turning centers are used to machine parts in two axes (X and Z). They are typically used for turning, boring, and drilling operations.

- Grinders: Grinders are used to finish machine parts to a high degree of precision. They are typically used for grinding, honing, and lapping operations.

CNC machines are controlled by a variety of different types of controls. The most common types of CNC controls include:

- G-code controls: G-code controls use a series of G-codes to tell the machine how to move. G-codes are a standardized language that is used by most CNC machines.

- M-code controls: M-code controls use a series of M-codes to tell the machine how to perform specific operations, such as starting and stopping the spindle or changing the tool.

- CNC software: CNC software is a computer program that allows you to create and edit CNC programs. CNC software can also be used to simulate the operation of a CNC machine.

CNC programs are written in a variety of different programming languages. The most common types of CNC programming languages include:

- G-code programming: G-code programming is a direct programming language that uses G-codes to tell the machine how to move.

- M-code programming: M-code programming is a indirect programming language that uses M-codes to tell the machine how to perform specific operations.

- Conversational programming: Conversational programming is a user-friendly programming language that allows you to create CNC programs using a graphical interface.

Here are a few tips and tricks for getting the most out of your FANUC CNC machine:

- Use the right tools for the job. Different types of CNC machines are designed for different types of operations. Make sure you are using the right type of CNC machine for the job you need to do.

- Use sharp cutting tools. Sharp cutting tools will produce cleaner cuts and will last longer than dull cutting tools.

- Follow the manufacturer's instructions. The manufacturer's instructions will provide you with the information you need to operate your FANUC CNC machine safely and efficiently.

- Use CNC software. CNC software can help you create and edit CNC programs, and it can also be used to simulate the operation of a CNC machine.

- Get training. If you are new to CNC machining, it is a good idea to get training from a qualified instructor. Training can help you learn how to operate your CNC machine safely and efficiently.

CNC machining is a powerful tool that can be used to produce a wide variety of parts with high precision and accuracy. FANUC is one of the leading manufacturers of CNC machines, and their machines are known for their reliability, durability, and ease of use. If you are new to CNC machining or if you want to improve your skills, this guide will provide you with everything you need to know about CNC operating skills for FANUC.

5 out of 5

| Language | : | English |

| File size | : | 613 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 21 pages |

| Lending | : | Enabled |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Top Book

Top Book Novel

Novel Fiction

Fiction Nonfiction

Nonfiction Literature

Literature Paperback

Paperback Hardcover

Hardcover E-book

E-book Audiobook

Audiobook Bestseller

Bestseller Classic

Classic Mystery

Mystery Thriller

Thriller Romance

Romance Fantasy

Fantasy Science Fiction

Science Fiction Biography

Biography Memoir

Memoir Autobiography

Autobiography Poetry

Poetry Drama

Drama Historical Fiction

Historical Fiction Self-help

Self-help Young Adult

Young Adult Childrens Books

Childrens Books Graphic Novel

Graphic Novel Anthology

Anthology Series

Series Encyclopedia

Encyclopedia Reference

Reference Guidebook

Guidebook Textbook

Textbook Workbook

Workbook Journal

Journal Diary

Diary Manuscript

Manuscript Folio

Folio Pulp Fiction

Pulp Fiction Short Stories

Short Stories Fairy Tales

Fairy Tales Fables

Fables Mythology

Mythology Philosophy

Philosophy Religion

Religion Spirituality

Spirituality Essays

Essays Critique

Critique Commentary

Commentary Glossary

Glossary Bibliography

Bibliography Index

Index Table of Contents

Table of Contents Preface

Preface Introduction

Introduction Foreword

Foreword Afterword

Afterword Appendices

Appendices Annotations

Annotations Footnotes

Footnotes Epilogue

Epilogue Prologue

Prologue Stuart G Yates

Stuart G Yates Kevin L Gyoerkoe

Kevin L Gyoerkoe Richard Wilbur

Richard Wilbur David Taransaud

David Taransaud Russell Thorburn

Russell Thorburn Camille Fournier

Camille Fournier Seanan Mcguire

Seanan Mcguire Jayaprakash Satyamurthy

Jayaprakash Satyamurthy Martha C Nussbaum

Martha C Nussbaum Yanis Varoufakis

Yanis Varoufakis Benjamin M Wallace

Benjamin M Wallace Nicole Zoltack

Nicole Zoltack Loreth Anne White

Loreth Anne White Simone Muench

Simone Muench Erskine Childers

Erskine Childers Stephen Cantrell

Stephen Cantrell R H Sin

R H Sin Lilian Mbithe

Lilian Mbithe Charlotte May

Charlotte May Simon King

Simon King

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Kenzaburō ŌeAn Uncensored History Of Darpa: America's Top Secret Military Research Agency

Kenzaburō ŌeAn Uncensored History Of Darpa: America's Top Secret Military Research Agency

Art MitchellMaking Sense of Consumer Data in the Digital World: A Comprehensive Guide for...

Art MitchellMaking Sense of Consumer Data in the Digital World: A Comprehensive Guide for... Giovanni MitchellFollow ·18.6k

Giovanni MitchellFollow ·18.6k Floyd PowellFollow ·9k

Floyd PowellFollow ·9k Osamu DazaiFollow ·3.2k

Osamu DazaiFollow ·3.2k Leo MitchellFollow ·8k

Leo MitchellFollow ·8k Donald WardFollow ·10.5k

Donald WardFollow ·10.5k Jean BlairFollow ·2.2k

Jean BlairFollow ·2.2k Herman MitchellFollow ·15.8k

Herman MitchellFollow ·15.8k Devin CoxFollow ·14.3k

Devin CoxFollow ·14.3k

Caleb Carter

Caleb CarterThe Complete Beagle Dog Beginners Guide: Beagle Facts,...

Beagles are...

Gage Hayes

Gage HayesThe Origins and Evolution of No Child Left Behind:...

The No Child Left Behind...

George Martin

George MartinThe Love Pirates: A Swashbuckling Tale of Love,...

The Love Pirates is a thrilling...

Nathaniel Hawthorne

Nathaniel HawthorneDifferentiating the Curriculum for Gifted Learners:...

Gifted learners are...

Carlos Fuentes

Carlos FuentesThe Years of Rice and Salt: A Journey Through a Forgotten...

The Years of Rice and Salt is...

Herbert Cox

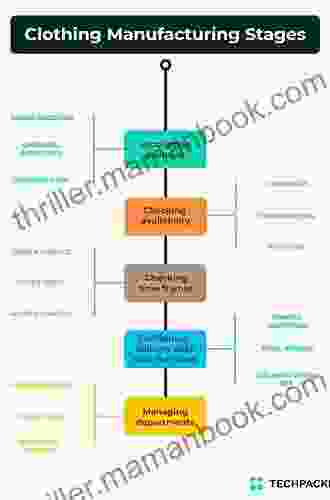

Herbert CoxThe Intricate Design of Clothing Manufacturing Processes:...

The clothing industry is a vast and...

5 out of 5

| Language | : | English |

| File size | : | 613 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 21 pages |

| Lending | : | Enabled |