Part Assembly Drawings Sheet Metal Surfacing: A Comprehensive Guide for Engineers and Designers

Table of Contents

4.2 out of 5

| Language | : | English |

| File size | : | 44947 KB |

| Screen Reader | : | Supported |

| Print length | : | 224 pages |

- Importance of Part Assembly Drawings for Sheet Metal Surfacing

- Projection Views

- Cross Sections

- Auxiliary Views

- Bend Tables

- Principles of Designing Sheet Metal Parts

- Software for Creating Part Assembly Drawings

- Best Practices for Part Assembly Drawings

Importance of Part Assembly Drawings for Sheet Metal Surfacing

Part assembly drawings are essential for accurately representing sheet metal parts and their assembly. These drawings provide detailed instructions on how to assemble the parts, ensuring proper fit and function.

For sheet metal surfacing, part assembly drawings are crucial for:

- Facilitating communication between engineers, designers, and fabricators

- Ensuring accurate fabrication of parts

- Simplifying assembly processes

- Reducing errors and rework

Projection Views

Projection views are the primary method for representing parts in part assembly drawings. They show the object from different angles, providing a comprehensive view of its shape and features.

There are three main types of projection views:

- Front view: Shows the object from the front

- Top view: Shows the object from above

- Side view: Shows the object from the side

Cross Sections

Cross sections are used to show the internal structure of a part. They are created by cutting the part along a specific plane and looking at the exposed surface.

Cross sections are essential for sheet metal surfacing, as they reveal the thickness of the material and the shape of the bends.

Auxiliary Views

Auxiliary views are used to show features of a part that cannot be fully represented in the projection views.

For example, an auxiliary view may be used to show the shape of a curved surface or the angle of a bend.

Bend Tables

Bend tables are used to specify the dimensions and locations of bends in sheet metal parts. They provide detailed information on the bend radius, bend angle, and bend allowance.

Bend tables are essential for ensuring that parts are bent to the correct shape and size.

Principles of Designing Sheet Metal Parts

When designing sheet metal parts for assembly, it is important to consider the following principles:

- Use standard bends: Standard bends are available in a variety of radii and angles, which simplifies fabrication and reduces costs.

- Minimize the number of bends: Each bend weakens the material, so it is important to minimize the number of bends used.

- Use gradual bends: Sharp bends can cause the material to crack or tear.

- Allow for bend radii: The bend radius must be large enough to prevent the material from stretching or tearing.

Software for Creating Part Assembly Drawings

There are a variety of software programs available for creating part assembly drawings. These programs can automate many of the tasks involved in drafting, such as creating projection views, cross sections, and bend tables.

Some popular software programs include:

- AutoCAD

- SolidWorks

- Inventor

- Creo

Best Practices for Part Assembly Drawings

When creating part assembly drawings, it is important to follow best practices to ensure accuracy and clarity.

Some best practices include:

- Use clear and concise lines: Lines should be sharp and well-defined.

- Label all views and features: Clearly identify all views, features, and dimensions.

- Use proper dimensioning: Dimensions should be accurate and easy to read.

- Include a title block: The title block should contain information about the part, such as the part number, revision level, and date.

Part assembly drawings are essential for communicating the design and assembly of sheet metal parts. By following the principles and best practices outlined in this guide, you can create accurate and comprehensive drawings that will ensure proper fabrication and assembly.

4.2 out of 5

| Language | : | English |

| File size | : | 44947 KB |

| Screen Reader | : | Supported |

| Print length | : | 224 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Top Book

Top Book Novel

Novel Fiction

Fiction Nonfiction

Nonfiction Literature

Literature Paperback

Paperback Hardcover

Hardcover E-book

E-book Audiobook

Audiobook Bestseller

Bestseller Classic

Classic Mystery

Mystery Thriller

Thriller Romance

Romance Fantasy

Fantasy Science Fiction

Science Fiction Biography

Biography Memoir

Memoir Autobiography

Autobiography Poetry

Poetry Drama

Drama Historical Fiction

Historical Fiction Self-help

Self-help Young Adult

Young Adult Childrens Books

Childrens Books Graphic Novel

Graphic Novel Anthology

Anthology Series

Series Encyclopedia

Encyclopedia Reference

Reference Guidebook

Guidebook Textbook

Textbook Workbook

Workbook Journal

Journal Diary

Diary Manuscript

Manuscript Folio

Folio Pulp Fiction

Pulp Fiction Short Stories

Short Stories Fairy Tales

Fairy Tales Fables

Fables Mythology

Mythology Philosophy

Philosophy Religion

Religion Spirituality

Spirituality Essays

Essays Critique

Critique Commentary

Commentary Glossary

Glossary Bibliography

Bibliography Index

Index Table of Contents

Table of Contents Preface

Preface Introduction

Introduction Foreword

Foreword Afterword

Afterword Appendices

Appendices Annotations

Annotations Footnotes

Footnotes Epilogue

Epilogue Prologue

Prologue Jamal Abukou

Jamal Abukou Orhan Pamuk

Orhan Pamuk Sharon Jensen

Sharon Jensen Anneke Vanmarcke Forzani

Anneke Vanmarcke Forzani Kim Stanley Robinson

Kim Stanley Robinson Natalie Homer

Natalie Homer Garry Goodman

Garry Goodman James A Michener

James A Michener Penelope Sky

Penelope Sky Kenneth Grahame

Kenneth Grahame Tom Antion

Tom Antion Gad Saad

Gad Saad Neal Sehgal

Neal Sehgal Becci Murray

Becci Murray Braeden Michaels

Braeden Michaels R C Majumdar

R C Majumdar Stuart G Yates

Stuart G Yates Vera Pavlova

Vera Pavlova William English

William English Marie Brennan

Marie Brennan

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Joseph ConradThe Widows of Malabar Hill by Perveen Mistry: A Gripping Mystery Steeped in...

Joseph ConradThe Widows of Malabar Hill by Perveen Mistry: A Gripping Mystery Steeped in...

Gabriel Garcia MarquezHow to Find and Keep Lasting Love: A Comprehensive Guide to Finding Your...

Gabriel Garcia MarquezHow to Find and Keep Lasting Love: A Comprehensive Guide to Finding Your... Reginald CoxFollow ·11.6k

Reginald CoxFollow ·11.6k Derek CookFollow ·15.6k

Derek CookFollow ·15.6k Desmond FosterFollow ·10.2k

Desmond FosterFollow ·10.2k Bret MitchellFollow ·2.4k

Bret MitchellFollow ·2.4k Houston PowellFollow ·15.5k

Houston PowellFollow ·15.5k Wesley ReedFollow ·15.7k

Wesley ReedFollow ·15.7k David BaldacciFollow ·6.4k

David BaldacciFollow ·6.4k Jared PowellFollow ·4.7k

Jared PowellFollow ·4.7k

Caleb Carter

Caleb CarterThe Complete Beagle Dog Beginners Guide: Beagle Facts,...

Beagles are...

Gage Hayes

Gage HayesThe Origins and Evolution of No Child Left Behind:...

The No Child Left Behind...

George Martin

George MartinThe Love Pirates: A Swashbuckling Tale of Love,...

The Love Pirates is a thrilling...

Nathaniel Hawthorne

Nathaniel HawthorneDifferentiating the Curriculum for Gifted Learners:...

Gifted learners are...

Carlos Fuentes

Carlos FuentesThe Years of Rice and Salt: A Journey Through a Forgotten...

The Years of Rice and Salt is...

Herbert Cox

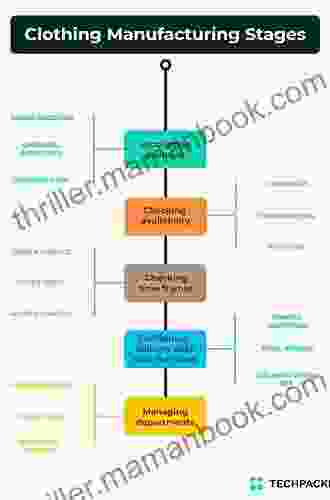

Herbert CoxThe Intricate Design of Clothing Manufacturing Processes:...

The clothing industry is a vast and...

4.2 out of 5

| Language | : | English |

| File size | : | 44947 KB |

| Screen Reader | : | Supported |

| Print length | : | 224 pages |